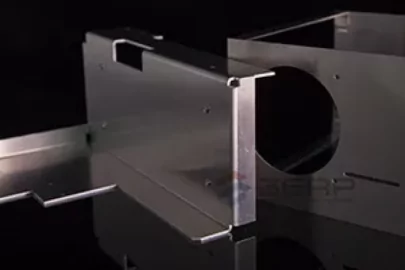

Sheet Metal Fabrication

Advantages of Sheet Metal Fabrication

1 Material selection

Aluminum + , copper, stainless steel + , steel and zinc

2 Finishing options

Bead blasting, anodizing, plating, powder coating and custom finishes

3 Thickness options

Variety of gauges available

4 Durability

Low setup costs mean low prices for large volumes

5 Scalability

Parts delivered in just 5-10 days

6 Turnaround

Parts delivered in just 5-10 days

Common Sheet Metal Applications

What is Sheet Metal Fabrication?

Sheet metal fabrication is a set of manufacturing processes used to turn sheet metal stock into functional parts. The sheet metal is usually between 0.006 and 0.25 inches (0.015 and 0.635 centimeters) thick.

There are several processes that fall under the umbrella of ‘sheet metal fabrication’. These include cutting, bending and punching, and can be used either in tandem or individually.

Sheet metal fabrication can be used to create either functional prototypes or end-use parts, but end-use sheet metal parts generally require a finishing process before they are ready for market.

How does sheet metal fabrication work?

Material Removal

Laser Cutting

Laser cutting uses a laser to cut the sheet metal part. A high-power laser is directed onto the sheet and intensified with a lens or mirror to a concentrated spot. In the specific application of sheet metal fabrication, the focal length of the laser varies between 1.5 to 3 inches (38 to 76 millimeters), and the laser spot size measures around 0.001 inches (0.025 mm) in diameter.

Laser cutting is more precise and energy-efficient than some other cutting processes, but cannot cut through all kinds of sheet metal nor the very highest gauges.

- Part accuracies of better than 0.002 inches (0.05 mm)

- Kerf widths of 0.006 inches (0.15 mm) to 0.015 inches (0.38 mm)

- Material versatility

Water Jet Cutting

A water jet cutter uses a high-pressure jet of water to penetrate the sheet metal. Unless the metal is especially thin, the water is mixed with an abrasive substance in order to cut through the solid material.

Since water jet cutting does not give off heat like laser or plasma cutting, the process is particularly useful for metals that have a low melting point and might otherwise deform. With water jet cutting, there is no heat-affected zone (HAZ), and metals can be cut without changing their intrinsic properties.

- Part accuracies of better than 0.002 inches (0.05 mm)

- Kerf widths of 0.006 inches (0.15 mm) to 0.015 inches (0.38 mm)

- Material versatility

Plasma cutting

Plasma jetting uses a jet of hot plasma to cut through the sheet metal. The process, which involves creating an electrical channel of superheated ionised gas, is fast and has a relatively low setup cost.

Thick sheet metal (up to 0.25 inches) is ideal for the plasma cutting process, since computer-controlled plasma cutters are more powerful than laser or water jet cutters. In fact, many plasma cutting machines can cut through workpieces up to 6 inches (150 mm) thick. However, the process is less accurate than laser cutting or water jet cutting.

- Part accuracies of better than 0.008 inches (0.2 mm))

- High cutting speed, e.g. 200 inches (5.08 meters) of 16-gauge mild steel per minute

- Material versatility

Punching

When the sheet metal needs to be punctured with holes, a designated punching machine is generally more efficient than the above cutting methods. Punching involves sandwiching the sheet between a punch and a die; when the punch moves into the die, it forces a hole in the sheet. The process can also be used to form irregular shapes, by making several small punches in series.

Most sheet metals can be punched, but the diameter of a round hole should generally be larger than the thickness of the chosen metal.

Material Deformation

Bending

Sheet metal bending is used to create V-shape, U-shape and channel shape bends using a machine called a brake. Most brakes can bend sheet metal to an angle of up to 120 degrees, but the maximum bending force is dependent on factors such as metal thickness and tensile strength.

In general, sheet metal must initially be over-bent, because it will partially spring back towards its original position.

Stamping

Stamping is another deformation process used to form sheet metal into a desired shape. The process uses a stamping die — either mechanic or hydraulic — to press the sheet metal into its new form.

Stamping is used on cold sheet metal, but the friction caused by the die causes the metal to heat up to high temperatures. Individual stamping processes include, but are not limited to.

- Coining, in which a pattern is pressed onto the sheet metal part

- Curling, in which the sheet metal is deformed into a tubular shape

- Hemming, in which sheet metal is folded on itself for extra thickness

- Ironing, in which the sheet metal part is reduced in thickness

Plasma cutting

Plasma jetting uses a jet of hot plasma to cut through the sheet metal. The process, which involves creating an electrical channel of superheated ionised gas, is fast and has a relatively low setup cost.

Thick sheet metal (up to 0.25 inches) is ideal for the plasma cutting process, since computer-controlled plasma cutters are more powerful than laser or water jet cutters. In fact, many plasma cutting machines can cut through workpieces up to 6 inches (150 mm) thick. However, the process is less accurate than laser cutting or water jet cutting.

- Part accuracies of better than 0.008 inches (0.2 mm))

- High cutting speed, e.g. 200 inches (5.08 meters) of 16-gauge mild steel per minute

- Material versatility

Material Assembly

Assembly

A product may be designed so that several sheet metal parts can be fitted together with joints, screws or other common methods.

This usually comes after the parts have undergone any required finishing processes.

Welding

Sheet metal parts sometimes need to be joined together using the process of welding, which fuses components together with heat.

Sheet metal materials like aluminium and stainless steel have high weldability.

Sheet Metal

FAQ’s

Do I need laser cutting, water jet cutting or plasma cutting?

The type of cutting machine used depends on the chosen material and the gauge of the sheet, as well as factors like desired lead time and tolerances.

We know which projects need which equipment, so you don’t need to specify a particular cutting machine.

Does it cost more to use multiple sheet metal forming processes?

In general, a part that is cut, bent and punched will cost more than a part that is, for example, just cut using a laser cutter.

However, most sheet metal parts demand a combination of forming processes, and this will not increase the price by a drastic amount.

Is there a minimum order quantity?

No. You can order a one-off prototype or 1,000+ units.

Put your parts into production today

All information and uploads are secure and confidential.